Our extensive SIMATIC controller range of solutions offers the perfect programmable logic controller, whatever your requirement. Whether for control tasks, integrating technology or archiving data – small-scale automation tasks to highly complex system solutions – failsafe or standard controller – a SIMATIC controller represents a secure investment for the future, and allows you to respond to new challenges quickly, flexibly and cost-effectively.

SIMATIC Modular Controller

The perfect SIMATIC controller for every application

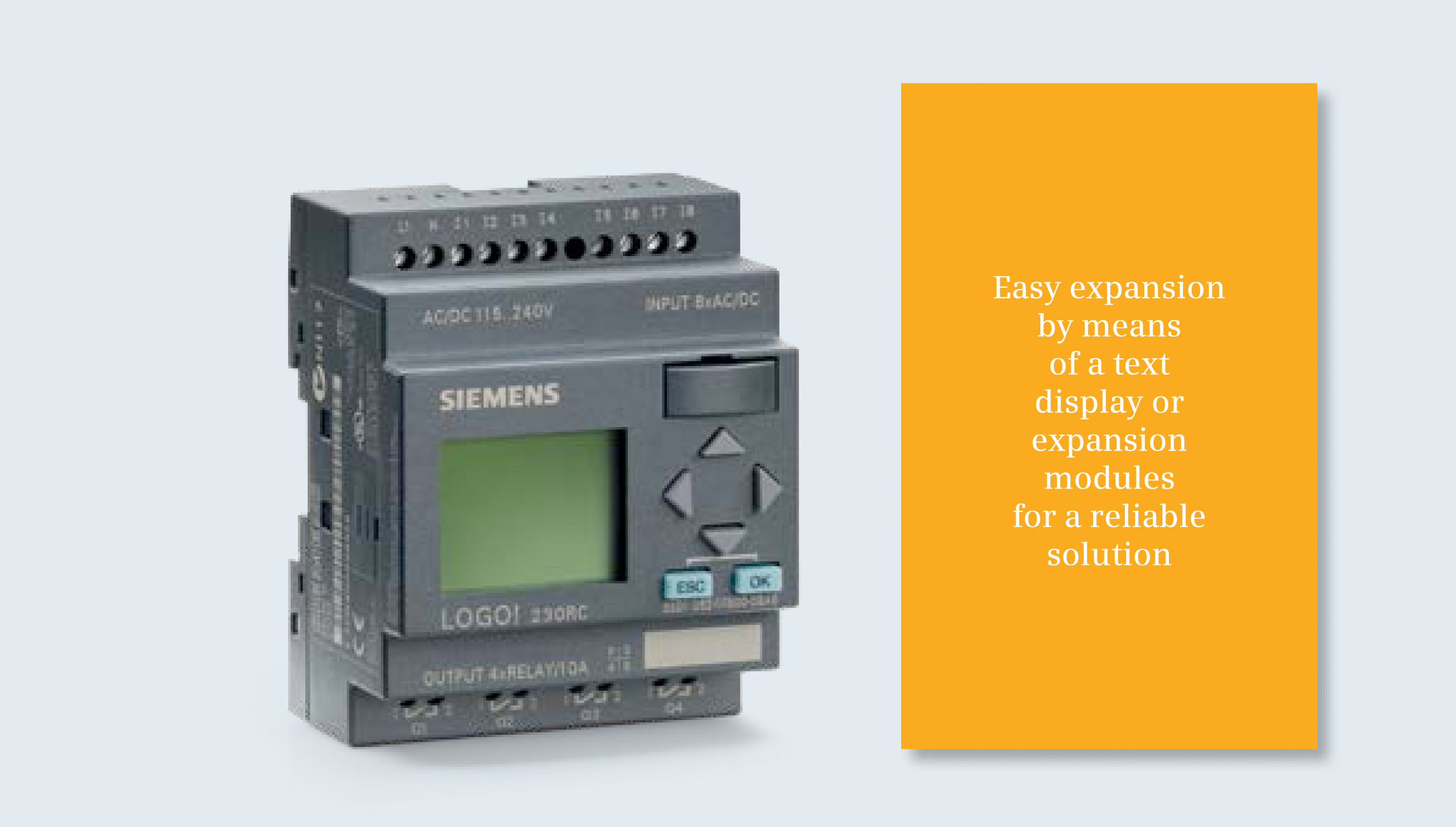

LOGO! Logic Modules: now twice as ingenious

LOGO! The compact, Easy-to-use and low cost solution for simple control tasks. With the logic module LOGO! System Siemens offers the ideal controller for simple automation tasks in industry and building services. The consistently modular design of LOGO! Makes it extremely flexible

LOGO! 0BA6

LOGO! 0BA6 basic units, together with the expansion modules and the external text display, provide a broad and proven basis for reliable in mechanical engineering and building management systems. Practice-oriented function blocks are easily connected via the software using cursor and their interaction can be immediately tested.

- 38/43 ready-to-use functions integrated

-no additional devices such as operating hours counter required - Linking of 200/400 functions possible

- 8 digital inputs (incl. 4 AI with 12/24 V DC)

- Flexibly expandable up to 24 DI, 16 DO, 8 AI, and 2 AO

- Display of message texts, actual and setpoint values and direct modification of the values on the display (not on Pure variants)

- Integrated data retentively – ensure backup of the current values in the event of a power failure

- Software LOGO! Soft Comfort V7 for the user-friendly creation of switching programs on the PC for all LOGO! generations, which can run on various operating systems

Highlights

- can be modularly expanded up to 50 I/Os

- 230 V units can be expanded with analog modules

- all three phases can be combined in a configuration

- extremely simple software

- display of up to 50 messages, either by LC display on the module, external TD, or both together

- support 12 or 16 standard character per line, depending on the selected character set;you can double the number of characters with the ticker function

- users can toggle between 2 languages

- display of up to 4 bar chart and up to 4 I/O status parameters per messages

- controllable backlight of both displays can also be used in continuous operation

- password protection for STOP mode on TD

LOGO! 0BA7

LOGO! 0BA7 impressively proves that we are constantly further developing our pioneering logic module. The two basic devices supplement the existing 0BA6 basic devices, which have already been tried and tested worldwide.

- Standard Ethernet interface as programming interface and for communication with other LOGO! basic devices 0BA7 or SIMATIC S7 CPUs, HMI Panels and PCs

- A maximum of 9 LOGO!s can be networked

- Data logging

- Standard SD cards as the storage medium

- Program and connection-compatible with LOGO! 0BA6

Communication like never before

Master/slave connections between LOGO! and LOGO!

In this case, only one of a maximum of 9 basic devices processes a user program. The others only serve to expand the I/O capacity. They provide the input information of the digital and analog inputs to the first LOGO! and execute the switching commands on the other side for the digital outputs of their hardware, or they forward the analog output values to the I/O. This does with the limitation on the number of channels of the previous basic devices. Of course, the basic devices that are being used as slaves can be equipped with the proven expansion modules up to the maximum process image.

Master/master connections between LOGO! and LOGO!

In this mode, up to 9 basic devices can also be connected to each other. However, each LOGO! processes its own program and shares only th generally needed information with the others. In this way, small, networked system with easy program structures can be created. Each unit can continue to solve its subtask without the others, if necessary. In both cases, up to 9 basic devices and a PC/PG for programming can be interconnected. The theoretical degree of expansion of a LOGO! configuration is thus 88 DI, 80 D!, 40 AI, and 18 AQ.

Communication with SIMATIC S7

The new LOGO! basic modules cna be coupled to higher-level automation structures (E.g. SIMATIC S7 CPUs or HMI Panels with Ethernet interface), because they can work with the standard S7 protocal. This allows, for example, the use of SIMATIC Touch Panels for operating a machine controlled by LOGO!. Of course, you can also combine these communication options as needed.

Micro PLC for basis automation tasks

COmpact and powerful: The SIMATIC S7-200 Micro PLC is fast, communication-capable and highly productive in real-time mode. The consistently modular design facilitates the creation of tailor-made, expandable solutions in the low-end performance range. The S7-200 Micro PLC from Siemens can be used as either a stand-alone Micro PLC solution or in conjunction with other controllers.

| SIMATIC product/family | ET 200S | ET 200pro | |

| Product Brief | Distributed, discretely-modular I/O system with local intelligence | ||

| with degree of protection IP20 | With degree of protection IP65/67 | ||

| Product range | 3 standard CPUs 2 fail-safe CPUs |

1 standard CPU 2 fail-safe CPUs |

|

| Performance | |||

| Execution time for bit operation min. | 0.06 µs | 0.025 µs (IM154-8FX) | |

| Memory | |||

| Main memory, max | 192 KB | 512 KB | |

| Load memory/mass storage, max | Micro Memory Card, 8MB | ||

| I/O devices | |||

| I/O address area, max | 2048/2048 bytes | 2048/2048 bytes | |

| Safety/availability | |||

| Fail-safety | * (F-CPUs) | * (F-CPUs) | |

| Fault tolerance | |||

| PC functions | |||

| Data acquisition and archiving | |||

| Engineering | |||

| Configuration/programming software | STEP 7/STEP 7 Professional from V5.x, STEP 7 from V11 in the TIA Portal | ||

| Programming languages | LD, FBD, IL, SFC, ST, S7-HiGraph, CFC | ||

| Communication | |||

| MPI | * | * | |

| PtP | |||

| AS-Interface | |||

| PROFIBUS | * (PN CPUs) | * | |

| PROFINET IO | * | * | |

| Web Server | * (PN CPUs) | * | |

Highlight

- Discretely modular configuration with multi-wire connection

- Multifunctional thanks to a wide range of modules

- Also available as expandable block I/O with integral DI/DO: SIMATIC ET 200S Compact

- Many of the ET200 components are also available in a SIPLUS extreme version for extreme environmental conditions, e.g. extended temperature range (-40/-25 … +60/+70ºC) and for use where there is corrosive atmosphere/condensation

- Modular design with extremely compact housing

- Multifunctional thanks to a wide range of modular

- Easy installation

Modular, compact controller for discrete and stand-alone automation solutions

The controller SIMATIC S7-1200 is extremely flexible, scalable nad seamlessly integrated into the Totally Integrated Automation (TIA) architecture. As a result, it works perfectly together with HMI, I/O, drives and software.

| SIMATIC product/family | ||

| Product Brief | Modular, compact controller for discrete and stand-alone automation solutions | |

| Product range | 5 compact CPUs | |

| Performance | ||

| Execution time for bit operation min. | 0.085 µs | |

| Memory | ||

| Main memory, max | 125 KB | |

| Load memory/mass storage, max | 4 MB (CPU 1217C) | |

| I/O devices | ||

| I/O address area, max | 1024/1024 bytes | |

| Safety/availability | ||

| Fail-safety | available soon | |

| Fault tolerance | ||

| PC functions | ||

| Data acquisition and archiving | * | |

| Engineering | ||

| Configuration/programming software | STEP 7 Basic V12 in the TIA Portal STEP 7 Professional V12 in the TIA Portal |

|

| Programming languages | LD, FBD, SCL | |

| Communication | ||

| MPI | ||

| PtP | * (Character-based serial comm.) | |

| AS-Interface | * (via CP with STEP 7 V11 SP2) | |

| PROFIBUS | * | |

| PROFINET IO | * | |

| Web Server | * (Smart Device Access, SIMATIC S7-1200 App) |

Scalable and flexible design:

The SIMATICS S7-1200 controller family has been designed with maximum flexibility to fit your individual machine requirements. This allows you to custom design your controller system to meet your needs; it also makes future system expansions quick and easy.

The SIMATICS S7-1200 controller family has been designed with maximum flexibility to fit your individual machine requirements. This allows you to custom design your controller system to meet your needs; it also makes future system expansions quick and easy.

Integrated Industrial Ethernet/PROFINET interface:

Integrated Industrial ethernet profinet interface The Industrial Ethernet/PROFINET interface integrated into SIMATIC S7-1200 offers seamless communication with distributed I/O with SIMATIC HMI Basic Panels for visualization adn additional controllers for CPU-to-CPU communication. Also with devices from third parties for extended integration possibilities as well as the SIMATIC STEP 7 Basic engineering system for configuring and programming.

Integrated Industrial ethernet profinet interface The Industrial Ethernet/PROFINET interface integrated into SIMATIC S7-1200 offers seamless communication with distributed I/O with SIMATIC HMI Basic Panels for visualization adn additional controllers for CPU-to-CPU communication. Also with devices from third parties for extended integration possibilities as well as the SIMATIC STEP 7 Basic engineering system for configuring and programming.

Integrated technology functions:

integrated technology functionsThe name SIMATIC has been synonymous with reliability in the field of automation for many years. Based on long years of experience, we have integrated our proven and innovative technology functions into our new controller – ranging from counting and measuring speed, position and duty cycle control to simple process control functionality. This wide variety of functionality enables you to solve a wide array of applications.

integrated technology functionsThe name SIMATIC has been synonymous with reliability in the field of automation for many years. Based on long years of experience, we have integrated our proven and innovative technology functions into our new controller – ranging from counting and measuring speed, position and duty cycle control to simple process control functionality. This wide variety of functionality enables you to solve a wide array of applications.

Programming with SCL:

Like the other controllers, the S7-1200 can now be programmed with the high-level language SCL (Structured Control Language).

The modular universal controller for the manufacturing industry

The SIMATIC S7-300 universal controller is specially designed for innovative system solutions in manufacturing, specifically the automative and packaging industrues.

This modular controller serves as an ideal universal automation system for centralized and decentralized configurations. Safety technology and motion control can be integrated with standard automation into this universal controller.

| SIMATIC product/family | ||

| Product Brief | Modular controllers for system solutions in production automation in the low to mid performance ranges | |

| Product range | 7 standard CPUs 7 compact CPUs 5 fail-safe CPUs 2 technology CPUs 1 fail-safe technology CPU |

|

| Performance | ||

| Execution time for bit operation min. | 0.004 µs (CPU 319) | |

| Memory | ||

| Main memory, max | 2 MB (CPU 319) 2.5 MB (CPU 319F) |

|

| Load memory/mass storage, max | Micro Memory Card, 8MB | |

| I/O devices | ||

| I/O address area, max | 8192/8192 bytes | |

| Safety/availability | ||

| Fail-safety | * (F-CPUs) | |

| Fault tolerance | ||

| PC functions | ||

| Data acquisition and archiving | ||

| Engineering | ||

| Configuration/programming software | STEP 7/STEP 7 Professional from V5.x, STEP 7 from V11 in the TIA Portal | |

| Programming languages | LD, FBD, IL, SFC, ST, S7-HiGraph, CFC | |

| Communication | ||

| MPI | * | |

| PtP | * | |

| AS-Interface | * | |

| PROFIBUS | * (also via CP) | |

| PROFINET IO | * (alos via CP) | |

| Web Server | * (PN CPUs) |

Highlights

The SIMATIC S7-300 has been designed for innovative system solutions with focus on manufacturing engineering, and as a universal automation system, it represents an optimal solution for applications in centralized and distributed configurations:

- The ability to integrate powerful CPUs with Industrial Ethernet/PROFINET interface, integrated technological functions, or fail-safe designs makes additional investment unnecessary

- The S7-300 can be set up in a modular configuration without the need for slot rules for I/O modules. Theres is a wide range of modules available both for the centralized and the distributed configuration with ET 200M

- The Micro Memory Card as a data and program memory makes a backup battery superfluous and saves maintenance costs. In addition, an associated project, including symbols and comments, can be stored on this memory card to facilitate service calls

- The Micro Memory Card also enables simple program or firmware updates without a programming device. The Micro Memory Card can also be used during operation for storing and accessing data. e.g. for measured value archieving or recipe processing

- In additional to standard automation, safety technology and motion control can also be integrated in an S7-300

- Many of the S7-300 components are also available in a SIPLUS extreme version for extreme environment conditions. e.g. extended temperature range (-40/-25 … +60/+70°C) and for use where there is corrosive atmosphere/condensation

SIMATIC S7-400: a powerful solution

Part of the SIMATIC process controller series, the S7-400 has been designed for system solution in the fields of manufacturing and process automation.

This process controller is ideal for data-intensive tasks that are especially typical for the process industry.

High processing speeds and deterministic reponse times ensure short machine cycle times on high speed machines in the manufacturing industry.

| SIMATIC product/family | ||

| Product Brief | Modular controllers for system solutions in production and process automation in the medium to upper performance ranges | |

| Product range | 10 standard CPUs 3 fail-safe CPUs 4 fault-tolerant CPUs (alos fail-safe) |

|

| Performance | ||

| Execution time for bit operation min. | 0.018 µs (CPU 417) | |

| Memory | ||

| Main memory, max | 30 MB (CPU 417) | |

| Load memory/mass storage, max | Memory Card 64 MB | |

| I/O devices | ||

| I/O address area, max | 16384/16384 bytes | |

| Safety/availability | ||

| Fail-safety | * (F/FH CPUs) | |

| Fault tolerance | * (H/FH CPUs) | |

| PC functions | ||

| Data acquisition and archiving | ||

| Engineering | ||

| Configuration/programming software | STEP 7/STEP 7 Professional from V5.x, STEP 7 from V11 in the TIA Portal |

|

| Programming languages | LD, FBD, IL, SFC, ST, S7-HiGraph, CFC | |

| Communication | ||

| MPI | * | |

| PtP | * (via CP) | |

| AS-Interface | ||

| PROFIBUS | * (also via CP) | |

| PROFINET IO | * (also via CP) | |

| Web Server | * (PN CPUs) |

Highlight

The following features make the SIMATIC S7-400 the most powerful controller:

- The S7-400 is expecially suitable for data-intensive tasks in the process industry. High processing speeds and deterministic respone times guarantee short machine cycle times on high-speed machines in the manufacturing industry. The high-speed backplane bus of S7-400 ensure efficient linking of central I/O modules

- The S7-400 is used preferably to coordinate overall plants and to control lower-level communications lines with slave stations; this is guaranteed by the high communication power and the integral interfaces

- The power of the S7-400 is scalable thanks to graded range of CPUs; the capacity for I/O is almost unlimited

- The power reserves of the CPUs enable new functions to be integrated without further hardware investment, e.g. processing of quality data, user-friendly diagnostics, integration into higher-level MES solutions or high-speed communication via bus systems

- The S7-400 can be structured in a modular way without any slot rules; there is a wide range of modules available both for centralized configurations and distributed structures

- The configuration of the distributed I/O of the S7-400 can be modified during operation. In additional, signal modules can be removed and inserted while live (hot swapping). This makes it very easy to expand the system or replace modules in the event of a fault

- The storage of the complete project data including symbols and comments on the CPU simplifies service and maintenance calls

- Safety engineering and standard automation can be integrated into a single S7-400 controller; plant availability can be increased through the redundant structure of the S7-400

- Many S7-400 components are also available in a SIPLUS extreme version for extreme environmental conditions, e.g. for use where is a corrosive atmosphere/condensation

Hot standby with SIMATIC S7-400H

The SIMATIC S7-400H is a controller with two H CPUs of the same type; in the event of a fault, changeover takes place from the master system to the standby station. It is suitable for fault-tolerant process with hot standby requirements (processes with changeover times shorter than 100ms).

The SIMATIC S7-400H is a controller with two H CPUs of the same type; in the event of a fault, changeover takes place from the master system to the standby station. It is suitable for fault-tolerant process with hot standby requirements (processes with changeover times shorter than 100ms).

Highlight

- Flexible and scalable hardware solution with redundant controllers, in order to minimize downtimes

- Different redundancy options:

Redundant I/O

Redundant fieldbuses - Bumpless changeover without loss of data

- Changes to the configuration and replacement of components during operation

- Simple integration of safety functionality

- Synchronization of the systems up to distances of 10 km are possible

- Many S7-400 components are also available in a SIPLUS extreme version for extreme environmental conditions, e.g. for use where there is a corrosive atmosphere/condensation

The ultimate plus in automation

The SIMATIC S7-1500 controller family with the high-end CPU 1518 is the new generation of controllers in the TIA Portal and marks a milestone in automation. It ensures highest efficiency and maximum usability for medium and high-end applications in machine and system automation.

| SIMATIC product/family | ||

| Product Brief | The modular controllers for applications in the medium to upper performance range for discrete automation | |

| Product range | 3 standard CPUs with display (diagonal up to 6.1 cm) Other coming soon |

|

| Performance | ||

| Execution time for bit operation min. | 0.01 µs (CPU 1516) | |

| Memory | ||

| Main memory, max | 6 MB (program 1 MB, data 5 MB) | |

| Load memory/mass storage, max | 2 GB (via Memory Card) | |

| I/O devices | ||

| I/O address area, max | 31/31 bytes | |

| Safety/availability | ||

| Fail-safety | Available soon | |

| Fault tolerance | ||

| PC functions | ||

| Data acquisition and archiving | * | |

| Engineering | ||

| Configuration/programming software | STEP 7 Professional from V12 in the TIA Portal | |

| Programming languages | LD, FBD, IL, SFC available soon, ST | |

| Communication | ||

| MPI | ||

| PtP | * (via CMs) | |

| AS-Interface | ||

| PROFIBUS | * | |

| PROFINET IO | * | |

| Web Server | * (PN CPUs) |

+Power

SIMATIC® S7-1500 offers advanced system performance and PROFINET as a standard onboard interface. It is the new standard for performance. Short system response times mean shortened machine cycle times – increasing productivity, and yielding faster return on investment.

√ Outstanding system performance for extremely short response times and highest control quality

√ Technology Integrated for perfect integration of drives through motion control functionalities and PROFIdrive

√ Security Integrated – integrated throughout for the optimal protection of investment

+Efficiency

SIMATIC S7-1500 is designed for optimal usability. Thanks to the many system innovations the controller can be installed, connected, and commissioned qucikly and easy. Engineering, project planning, and the use of new functionalities are easier than ever before due to the seamless integration with TIA Portal. The TIA Portal provides intuitive navigation, workflow, and look and feel via a shared layout and navigation concept as well as shared consistent data storage for PLCs, HMIs, and Drives.

√ Innovative design and easy handling for simple use and commissioning as well as safe operation

√ Integrated system diagnostics for full transparency of the plant status, automatically generated and consistently displayed

√ TIA Portal for maximum engineering efficiency and reduced project costs